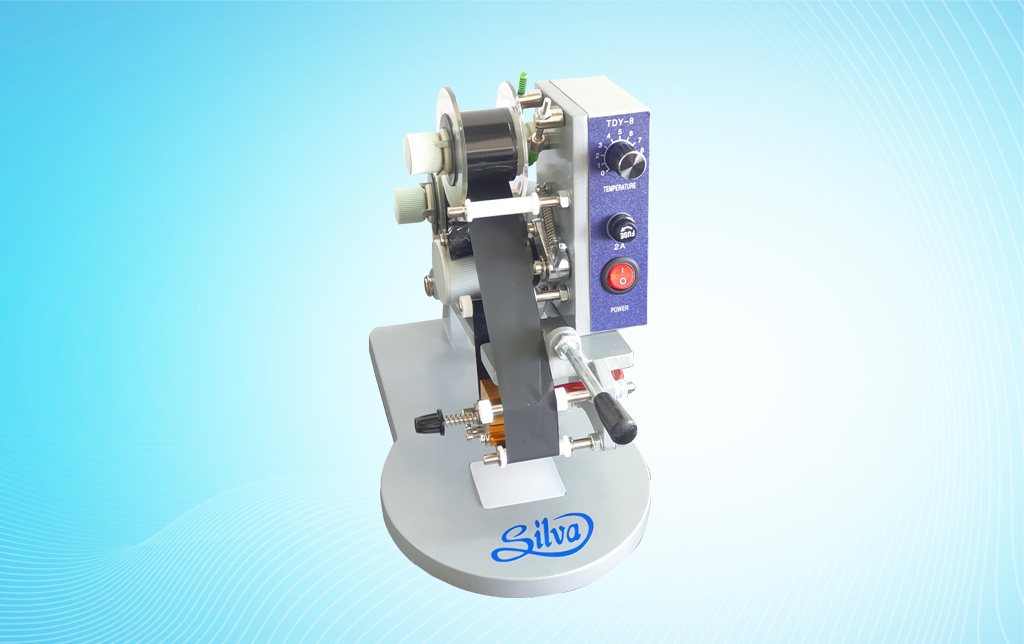

HANDY BATCH COADING MACHINE

Features

The key features of this machine are:

Thermal Printing Ribbon

The use of thermal printing ribbon ensures that there are no oil contamination worries, maintaining product, hand, and mechanical hygiene, especially crucial for industries like food and pharmaceuticals.

Hygiene and Cleanliness

The machine's design and ribbon choice ensure that the printing process maintains hygiene and cleanliness standards, critical in industries where product safety is a priority.

Automatic Continuous Printing

The machine offers automatic continuous printing functionality, enhancing efficiency and consistency in the printing process. It can also be controlled using a foot switch for manual operation.

Precision Design

The machine's rational and precision design contributes to its high-quality performance and ease of maintenance.

Flexible Word Structure

The unique word structure of the machine allows for easy handling and printing on various flexible packaging materials, ensuring versatility in coding.

Thermostatic Control

The machine features thermostatic control with adjustable temperature settings suitable for different materials and ribbons. This ensures optimal printing results and adhesion.

Clear and Instant Printing

The machine provides clear and legible printing results with instant printing and quick drying capabilities. The strong adhesion ensures that the print remains intact.

Wide Range of Applications

The machine is suitable for a variety of materials, including paper, cardboard, leather, plastic film, shrink film, and aluminum foil. It can print crucial information such as production date, batch number, origin, weight, price, size, composition, distributors, and manufacturers.

Ease of Maintenance

The machine is designed for easy maintenance, reducing downtime and ensuring consistent performance.

User-Friendly

The machine's design makes it user-friendly and straightforward to operate, allowing operators to perform the printing process efficiently.

Versatility

The machine's ability to print on various packaging materials and handle different types of information makes it versatile for a wide range of industries.

Product Safety

The thermal printing ribbon eliminates the risk of ink contamination, ensuring that products remain safe and free from any potential ink-related concerns.

Enhanced Traceability

The machine aids in maintaining accurate product traceability by printing essential information directly on the packaging.

Quality Assurance

The machine's precision machining and high-quality performance ensure consistent and reliable printing results.

Efficiency

The automatic continuous printing feature increases production efficiency and reduces the time required for manual coding.

Application

Food Industry

The machine is widely used in the food industry for printing essential information such as production dates, batch numbers, weight, and other details on packaging materials. It ensures product traceability and compliance with labeling regulations.

Beverage Industry

In the beverage industry, the machine is utilized to print batch codes, manufacturing dates, and other relevant information on bottles, cans, and other packaging materials.

Pharmaceutical Industry

The machine is crucial in the pharmaceutical sector for printing batch numbers, expiration dates, and other important data on medicine packaging, ensuring safety and regulatory compliance.

Cosmetics Industry

It is applied in the cosmetics industry to print manufacturing and expiry dates, batch codes, and other details on product packaging, maintaining product quality and safety.

Personal Care Products

The machine is used to print information like manufacturing dates, ingredients, and batch numbers on products such as shampoos, lotions, and skincare items.

Packaged Foods

It is employed to print date codes, lot numbers, and weight information on packaged foods, ensuring accurate labeling and traceability.

Snack Foods

The machine is used to print manufacturing dates, best-before dates, and batch numbers on snack food packaging.

Bakery Products

It is applied to print batch numbers, production dates, and other information on bakery products such as bread, pastries, and cakes.

Beverage Packaging

The machine is used to print essential details on beverage packaging, including bottles, cans, and cartons, enhancing traceability and consumer information.

Dairy Products

It is utilized to print information on dairy product packaging, such as milk, yogurt, and cheese, ensuring freshness and product authenticity.

Medicinal Products

In the pharmaceutical industry, the machine prints vital information on medication packaging, including dosage instructions, lot numbers, and expiration dates.

Nutraceuticals

The machine is employed for printing on packaging for dietary supplements, vitamins, and other health-related products.

Health and Wellness Products

It is used to print details on products promoting health and wellness, such as herbal supplements and natural remedies.

Convenience Foods

The machine is applied to print information on convenience foods like ready-to-eat meals and microwaveable products.

Non-Food Products

The machine can also be used to print essential details on non-food items such as cleaning products, detergents, and household goods.

Technical Specification

| Voltage | AC Voltage: 220V Frequency: 50 Hz |

| Power Consumption | 40W |

| Printing Speed | 10-25 times per minute |

| Temperature Range | 0°C to 200°C |

| Letter Size | 3 lines, 2x3mm |

| Machine Weight | 4 kg |

| Printing Method | Utilizes a handy batch coding method for marking products. |

| Efficient Power Usage | Energy-efficient operation with a power consumption of 40W. |

| Variable Printing Speed | Adjustable printing speed between 10 to 25 times per minute, catering to different production requirements. |

| Temperature Control Precision | Temperature range spanning from 0°C to 200°C, offering flexibility for different materials. |

| Clear Letter Size | Capable of printing clear and precise lettering with a letter size of 3 lines, 2x3mm. |

| Lightweight Design | Lightweight and easy-to-handle machine weighing only 4 kg. |

| User-Friendly Application | Designed for ease of use and simple operation. |

| Compact and Portable | Compact design and lightweight build make it easily portable within a production environment. |

| Letter Marking Flexibility | Suitable for marking batch codes, dates, or other relevant information on various products. |

| Compliance | Manufactured in compliance with industry standards for safety and quality. |

| Warranty | Standard warranty coverage for manufacturing defects and operational issues. |

Application Gallery