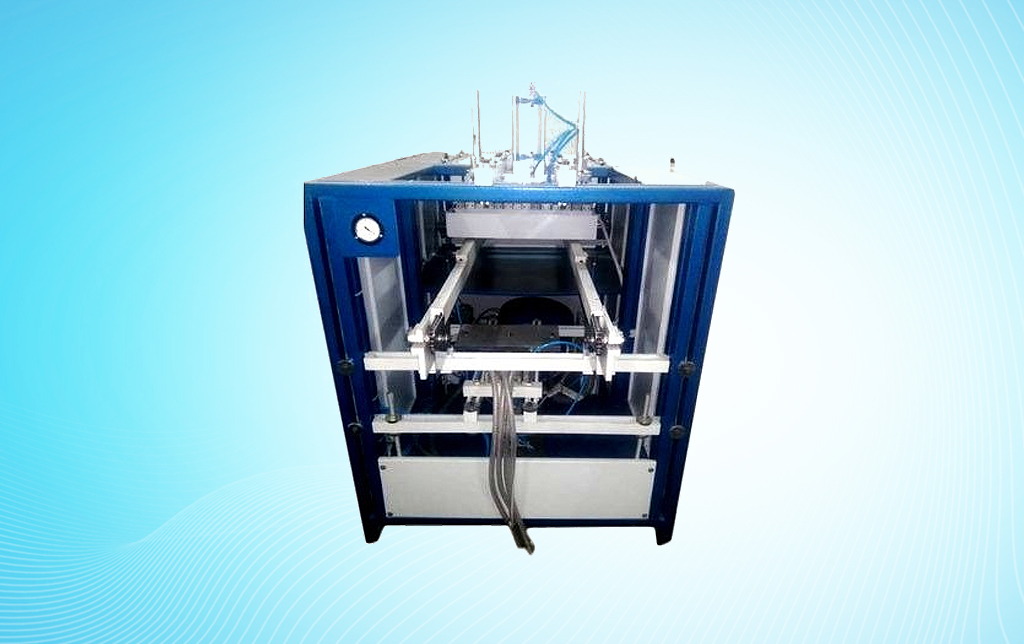

HEAVY DUTY AUTOMATIC BLISTER FORMING MACHINE

Features

The key features of this machine are:

Tailor-Made to Suit Specific Requirement

The machine is custom-built to meet specific packaging needs, allowing businesses to design blister packs that perfectly fit their products, ensuring optimal packaging and presentation.

Simple & Compact Design

The machine is designed with simplicity and compactness in mind, making it easy to integrate into existing production lines or limited workspace areas.

Easy to Operate

The machine is user-friendly and straightforward to operate, requiring minimal training for operators to achieve efficient blister forming.

Easy to Maintain

The machine's simple design and well-organized components make it easy to maintain, reducing downtime and increasing overall productivity.

Versatility

The tailor-made nature of the machine enables it to handle various blister sizes, shapes, and materials, providing versatility for different product packaging requirements.

Precise Blister Forming

The machine ensures accurate blister forming, maintaining uniformity and consistent quality in each package.

Programmable Controls

The machine may incorporate programmable controls for temperature, pressure, and other settings, allowing for precise adjustments to suit different blister materials and product types.

High-Quality Construction

The machine is built with durable and high-quality materials, ensuring reliability and longevity for continuous operation.

Safety Features

The machine may include safety features to protect operators during the blister forming process, ensuring a safe working environment.

Cost-Effective Solution

The tailor-made design and ease of operation and maintenance contribute to cost-effectiveness, reducing production costs and improving overall efficiency.

Customization

The machine's tailor-made nature enables businesses to create blister packs that perfectly fit their products, enhancing product protection and presentation.

Space Efficiency

The simple and compact design optimizes floor space, making the machine suitable for various production environments.

Quick Setup

The easy-to-operate design and minimal maintenance requirements allow for quick setup and changeover, minimizing downtime between different production runs.

Time and Labor Savings

The machine's user-friendly interface and precise blister forming capabilities reduce the need for extensive operator training and manual interventions.

Consistent Quality

The machine's accurate blister forming process ensures uniformity and consistent quality in each package, improving overall product appearance.

Adaptability

The versatility of the machine allows businesses to package various product types with different blister materials, catering to diverse packaging needs.

Durability

The high-quality construction ensures the machine's durability, reducing the need for frequent repairs or replacements.

Application

Powder coated structure

Blister forming machine with Powder coated structure for rust free, better & long lasting finish.

Electronic driven

Blister forming machine with Electronic driven advancement with immediate adjustment & 0.1 mm accuracy.

Virtually negligible

Blister forming machine with Virtually negligible power consumption.

Adjustable Width

Blister forming machine with adjustable width by means of reducing frames & adjustable width of the chain pacing.

Robust Construction

Blister forming machine with robust construction & heavy duty finish makes the machine maintenance free.

Instantaneous vacuum

Blister forming machine with instantaneous vacuum as it includes a high outflow vacuum pump attached to a large vacuum tank.

High-speed pneumatic

Blister forming machine with high-speed pneumatic movements.

Fully Automatic Cycle

Blister forming machine with fully automatic cycle for the production & manual movement for the adjustments of the mould.

Permanent Plug Assist

Blister forming machine with built-in permanent Plug Assist arrangement for deep draw articles.

Easy Operation

Blister forming machine which, allows great output with easy operation, by using inexpensive patterns.

Pressure Gauge

Blister forming machine with filter regulator with pressure gauge is provided on all the machines ensuring only clean air enters the costly pneumatics reducing the down time.

Excellent Electrical

Blister forming machine with excellent electrical & pneumatic components & high performance vacuum pump of reputed make makes the machine work smoothly for years to come.

Compact Size

Blister forming machine with very compact size, saves precious space.

Cooling

Blister forming machine with plate cooling instead of die cooling reduces cost of the dies substantially.

Toys

The machine can create blister packs for toys of different shapes and sizes, providing attractive and secure packaging for action figures, dolls, small cars, and other playthings.

Hardware

It is ideal for packaging small hardware items like screws, nuts, bolts, washers, and other fasteners, offering organized and easily accessible storage and display.

Electronic Parts

The machine can handle blister packaging for electronic components such as resistors, capacitors, diodes, connectors, and small circuit boards, ensuring protection and easy identification.

Drugs and Pharmaceuticals

It is well-suited for packaging pharmaceutical products like tablets, capsules, pills, and vials, providing tamper-evident and hygienic packaging.

Food Stuffs

The machine can package small food items such as candies, chocolates, gum, mints, and other confectionery products, preserving freshness and product quality.

Automobile Parts

It is suitable for packaging small automotive parts like fuses, spark plugs, electrical connectors, and other spare parts, ensuring safe storage and easy handling.

Kitchenware

The machine can create blister packs for small kitchenware items like cutlery sets, cooking utensils, measuring tools, and small kitchen gadgets.

Toiletries

It is suitable for packaging toiletry items like travel-sized soaps, shampoos, lotions, and personal care products, providing a convenient and hygienic packaging solution.

Cosmetics

The machine can package cosmetic products like lipsticks, mascaras, eyeliners, compact powders, and nail polishes, offering a professional and visually appealing presentation.

Miscellaneous Products

The machine's versatility allows it to package various other products, including stationery items, promotional goods, hardware accessories, and small household items.

Additional Information:

1. Pay Mode Terms: T/T (Bank Transfer),D/P,D/A

2. Port of Dispatch: Mumbai

3. Production Capacity: 100

4. Delivery Time: 1 month

5. Packaging Details: Export Quality

Technical Specification

| Packaging Type | wooden box |

| Model Name/Number | EP 1812 |

| Weight | 800 KG |

| Colour | Royal Blue |

| Type of heaters | Ceramic |

| Forming area | 18x21 inches |

| Forming depth | 100 mm |

| Forming Material | PS,PVC,PET |

BLISTER FORMING MACHINE

Application Gallery