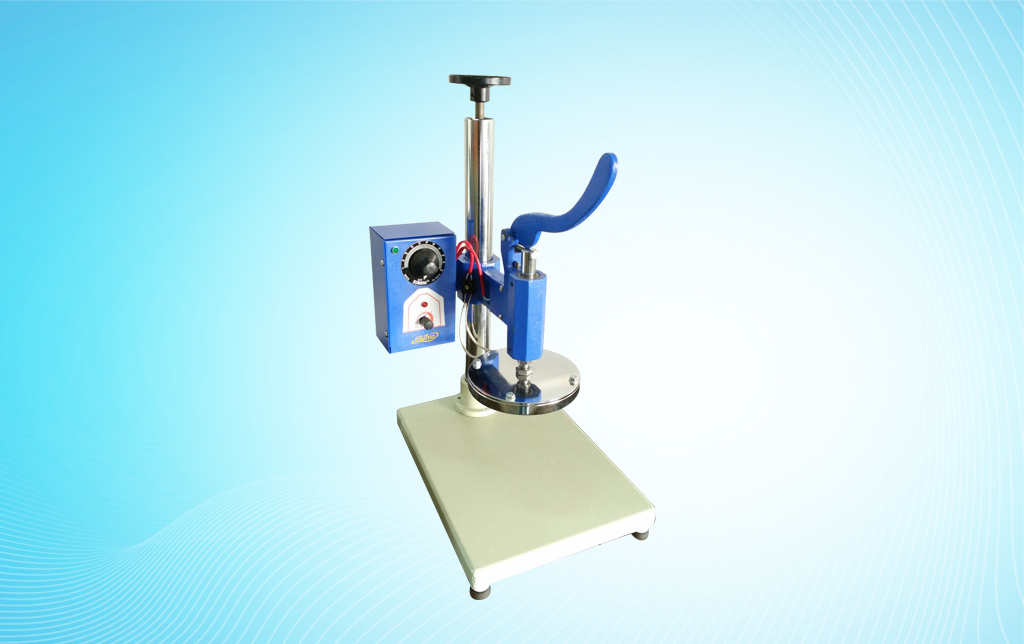

HEAVY DUTY FOIL SEALING MACHINE

Features

The key features of this machine are:

Easy Location of Plastic Container

The machine is designed to facilitate the easy positioning of plastic containers beneath the heating pad, ensuring accurate and efficient sealing.

Effortless Compression Spring Pressing Device/Lever

The machine is equipped with a compression spring pressing device or lever that allows for easy and effortless pressing during the sealing operation, reducing operator fatigue.

Adjustable Sealing Pad Height

The machine offers the capability to adjust the height of the sealing pad to accommodate different sizes of plastic containers, ensuring proper sealing regardless of container dimensions.

Thermostat for Temperature Control

The machine features a thermostat that allows for temperature control, enabling adjustments according to the thickness of the plastic cap or foil being used.

Accurate Sealing Positioning

The easy location feature ensures that plastic containers are positioned accurately beneath the heating pad, preventing misalignment and wastage.

Operator Comfort

The effortless compression spring pressing device or lever reduces the physical effort required from the operator during the sealing process, enhancing operator comfort and efficiency.

Versatility

The adjustable sealing pad height feature allows the machine to accommodate a variety of plastic container sizes, offering versatility in packaging.

Optimal Temperature Control

The thermostat feature enables precise temperature adjustments, ensuring that the plastic cap or foil is properly sealed based on its thickness. This helps prevent under-sealing or over-sealing.

Application

Plastic Containers

The machine is suitable for sealing various types of plastic containers, including jars, tubs, and canisters, ensuring airtight packaging and product freshness.

Plastic Cups

It can be used to seal plastic cups containing beverages, dairy products, desserts, and other consumables, preventing leakage and maintaining product quality.

Plastic Bottles

The machine is well-suited for sealing plastic bottles containing beverages, sauces, condiments, and liquid products, offering reliable packaging and preventing contamination.

Aluminum Foil Sealing

The machine is capable of sealing containers with aluminum foil lids, creating a tamper-evident seal that ensures product safety and freshness.

Plastic Cap Sealing

It can seal plastic containers with plastic caps, ensuring proper closure and preventing spillage during transportation and storage.

Food Products

The machine is suitable for sealing containers of various food products such as sauces, condiments, snacks, and dairy items, preserving freshness and preventing contamination.

Beverages

It can be applied to seal cups and bottles of beverages like juices, smoothies, milkshakes, and energy drinks, maintaining the flavor and quality of the contents.

Cosmetics and Personal Care

The machine can seal plastic containers of cosmetic products like creams, lotions, and gels, ensuring hygienic packaging and preventing leakage.

Pharmaceuticals

It is well-suited for sealing plastic containers of pharmaceutical products, medical supplies, and vitamins, ensuring tamper-evident packaging and product integrity.

Industrial Chemicals

The machine can be used to seal plastic containers of industrial chemicals, adhesives, and solvents, ensuring safe packaging and transport.

Dairy Products

It is suitable for sealing plastic containers of dairy products such as yogurt, cream, and milk, preventing contamination and maintaining freshness.

Condiments and Sauces

The machine can seal plastic containers of condiments, sauces, dressings, and spreads, preventing spillage and ensuring cleanliness.

Technical Specification

Technical Specification

| Sealing Diameter | 150mm (6 inches) |

| Max. Product Height | 10 inches |

| Power Supply | Voltage: Single Phase 220V Frequency: 50 Hz |

| Power Consumption | 550W |

| Dimensions | Length (L): 11 inches Breadth (B): 14 inches Height (H): 21 inches |

| Weight | 15 kg |

| Sealing Mechanism | Sealing mechanism utilizing heat and pressure to seal aluminium foil onto containers. |

| Construction Material | The machine body is constructed using durable materials for long-lasting performance and reliability. |

| Control Panel | User-friendly control panel for easy operation and adjustments. Includes a power switch, temperature control settings, and sealing time adjustments. |

| Sealing Process | The machine employs a high-precision sealing process to ensure tight and secure sealing of aluminium foil on containers. |

| Sealing Speed | The sealing process is designed for efficient and consistent sealing with adjustable speed settings. |

| Safety Features | Overheat protection to prevent the machine from operating at excessively high temperatures. Emergency stop button for immediate shutdown in case of any issues. |

| Cooling System | Equipped with a cooling system to maintain optimal operating temperatures during prolonged usage. |

| Sealing Indicator | LED indicators to display the status of the sealing process (e.g., ready, sealing in progress, completed). |

| Maintenance | Designed for easy maintenance and cleaning to ensure continuous and trouble-free operation. |

| Operating Environment | The machine is designed to operate in an indoor environment with controlled temperature and humidity conditions. |

| Warranty | Comes with a standard warranty period covering manufacturing defects and operational issues. |

| Additional Accessories | The machine may come with accessories such as spare sealing elements and user manual for proper guidance. |

| Compliance | The machine is designed and manufactured in compliance with relevant safety and quality standards. |

| Packaging | The machine will be securely packaged to prevent damage during transportation. |

ALLUMINIUM FOIL SEALING MACHINE

Application Gallery