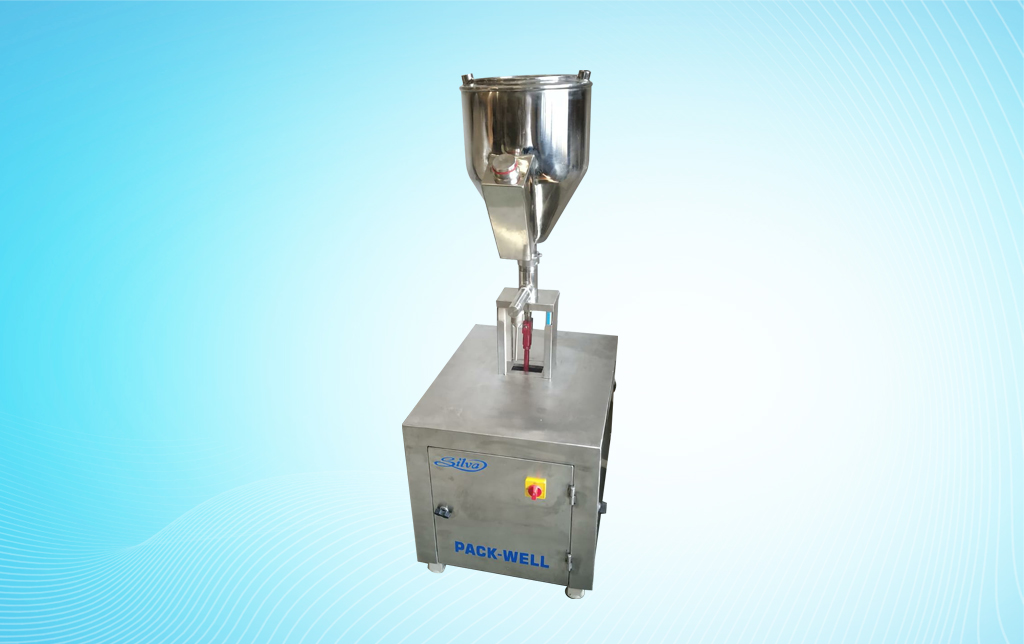

S.S. JACKETED PEST FILLING MACHINE (HEAVY DUTY)

Features

The key features of this machine are:

Twin Heads Configuration

The machine is equipped with two filling heads, allowing it to fill multiple containers simultaneously, thereby increasing productivity.

High Accuracy Filling

The machine is designed to achieve precise and accurate dosing of chuna or lime paste, ensuring consistency in each filled container.

Dosing Controls

The machine may incorporate advanced dosing controls, such as volume adjustment and flow rate regulation, enabling fine-tuning of the filling process for different container sizes and product viscosities.

Non-Drip Filling Nozzles

The machine is equipped with non-drip filling nozzles, minimizing product wastage and maintaining a clean and hygienic working environment.

Stainless Steel Construction

The machine may feature a stainless steel construction, ensuring durability, corrosion resistance, and compliance with hygiene standards.

Quick Changeover

The machine is designed for easy and quick changeover between different container sizes or product types, reducing downtime during production.

User-Friendly Interface

The machine's interface is designed to be user-friendly, making it easy for operators to set up and control the filling process.

Safety Features

The machine may include safety measures, such as emergency stop buttons and safety guards, to protect operators and prevent accidents during operation.

High Productivity

The twin heads configuration and high accuracy filling allow the machine to achieve high productivity rates, enhancing overall efficiency.

Easy Maintenance

The machine's design and construction allow for easy maintenance, reducing downtime and ensuring consistent performance.

Increased Productivity

The twin heads configuration and high accuracy filling enable the machine to fill multiple containers simultaneously, leading to increased productivity and output.

Consistent Filling

The high accuracy filling ensures consistent dosing of chuna or lime paste in each container, maintaining product quality and customer satisfaction.

Reduced Product Wastage

The non-drip filling nozzles prevent product spills and wastage, optimizing resource usage and minimizing production costs.

Enhanced Hygiene

The stainless steel construction and non-drip filling nozzles promote hygienic filling, ensuring the product's safety and quality.

Flexibility

The dosing controls and quick changeover capabilities allow the machine to handle various container sizes and adapt to different product specifications.

Operator Convenience

The user-friendly interface and safety features provide a safe and efficient working environment for operators.

Cost Efficiency

The high accuracy filling and reduced wastage contribute to cost savings and improved profitability.

Application

Lubricants

The machine can accurately fill lubricants such as engine oil, industrial grease, and specialty lubricants into containers of various sizes, ensuring precise and mess-free packaging.

Cosmetics

It is ideal for filling cosmetic products like creams, lotions, serums, and gels into jars, bottles, or tubes, providing precise and consistent dosing for aesthetic and hygienic packaging.

Food Products

The machine can handle various food products such as sauces, condiments, dressings, and pastes, ensuring accurate filling for attractive and convenient packaging.

Pharmaceuticals

It is well-suited for filling pharmaceutical products like ointments, creams, gels, and lotions into tubes, jars, or bottles, meeting the high standards of the pharmaceutical industry.

Adhesives

The machine can efficiently fill adhesives and sealants into tubes, cartridges, or containers, providing controlled and precise dispensing.

Gels and Pastes

It is suitable for filling gels and pastes used in personal care products, oral care products, and medical applications into suitable containers.

Hand Sanitizers

The machine can accurately fill hand sanitizers into bottles or dispensers, ensuring proper dosage for effective hygiene and safety.

Greases

It is ideal for filling greases into cartridges, tubs, or containers, catering to the lubrication needs of industrial and automotive applications.

Wax Products

The machine can accurately fill various wax-based products like candles, wax melts, and wax blocks, ensuring precise and uniform filling.

Petrolatum Products

The machine can handle filling petrolatum-based products like lip balms and petroleum jellies into containers, maintaining accurate and consistent dosing.

Technical Specification

| FILLING RANGE | 1 KG. |

| MACHINE SIZE | 31"X27"X71" (LXBXH) |

| POWER LOAD | 2 KW, SINGLE PHASE |

| WEIGHT | 250 KG. |

FILLING MACHINE

Application Gallery